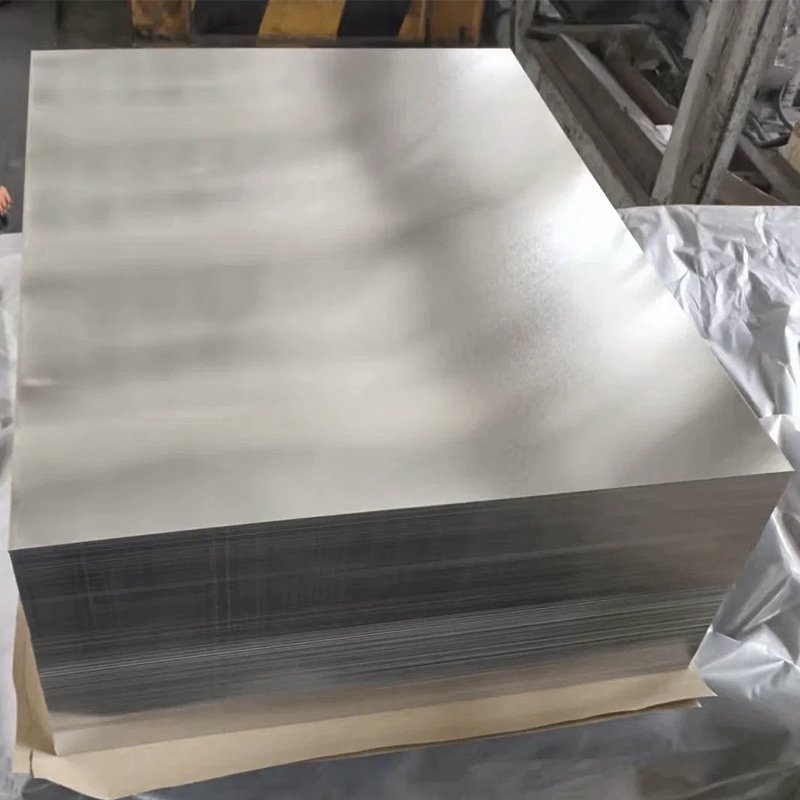

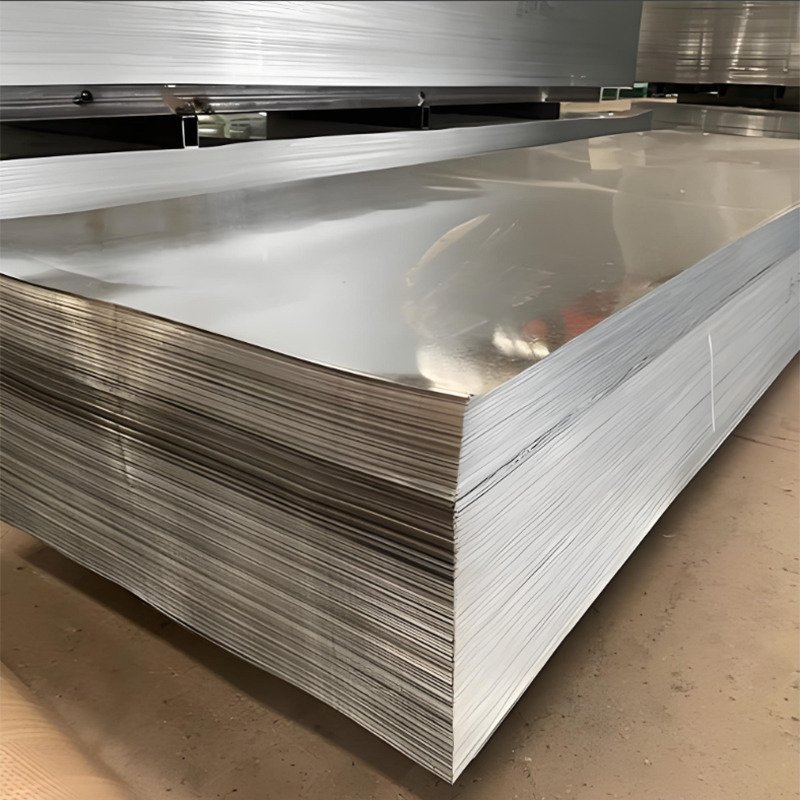

Tinplate is a thin steel sheet coated by tin. It has an extremely beautiful metallic luster as well as excellent properties in corrosion resistance, solderability, and weldability. Tinplate is used for making all types of containers such as food cans, beverage cans, 18-liter cans, and artistic cans. Its applications are not limited to containers; recently, tinplate has also been used for making electrical machinery parts and many other products.

PRODUCT DIMENSION

| Item | Temper | Thickness(mm) | Width(mm) | Length(mm) | Weight(mt) | Inner Dia. (mm) | ||||||||||||

| Coil | T1-T5 DR7-DR9 | 0.115-0.5 | 600-1050 | --- | 3-8 | 508 | ||||||||||||

| Sheet | T1-T5 DR7-DR9 | 0.115-0.50 | 600-1050 | 600-1200 | Max.2 | --- | ||||||||||||

HARDNESS/TEMPER

| Temper | Chinese Standard GB/T2520 | Japanese Standard JIS G3303 | American Standard ASTM A623M | European Standard DIN EN 10203 | International Standard ISO11949 | |||||||||||||

| T-1 | TH50+SE | T-1 | T-1(T49) | TS230 | TH50+SE | |||||||||||||

| T-2 | TH52+SE | T-2 | T-2(T53) | TS245 | TH52+SE | |||||||||||||

| T-2.5 | TH55+SE | T-2.5 | T-2.5(T55) | TS260 | TH55+SE | |||||||||||||

| T-3 | TH57+SE | T-3 | T-3(T57) | TS275 | TH57+SE | |||||||||||||

| T-4 | TH61+SE | T-4 | T-4(T61) | TH415 | TH61+SE | |||||||||||||

| T-5 | TH65+SE | T-5 | T-5(T65) | TH435 | TH65+SE | |||||||||||||

| DR7 | H71+SE | DR7 | DR7(T71) | TH520 | H71+SE | |||||||||||||

| DR8 | H73+SE | DR8 | DR8(T73) | TH550 | H73+SE | |||||||||||||

| DR9 | H76+SE | DR9 | DR9(T76) | TH620 | H76+SE | |||||||||||||

TIN COATING

| Type of Coating | Designation of coating weight | Nominal coating weight | Minimun ave. coating weight | |||||||||||||||

| Jis | Astm | g/m² | 1b/BB | g/m² | 1b/BB | |||||||||||||

| Equally Coating | 1.1/1.1 | #10 | 1.1/1.1 | 0.10 | 0.9/0.9 | 0.08 | ||||||||||||

| 2.8/2.8 | #25 | 2.8/2.8 | 0.25 | 2.45/2.45 | 0.22 | |||||||||||||

| 5.6/5.6 | #50 | 5.6/5.6 | 0.50 | 5.05/5.05 | 0.47 | |||||||||||||

| Differentially Coating | 1.1/2.8 | #10/25 | 1.1/2.8 | 0.10/0.25 | 0.9/2.45 | 0.08/0.11 | ||||||||||||

| 2.8/5.6 | #25/50 | 2.8/5.6 | 0.125/0.25 | 2.25/5.05 | 0.11/0.23 | |||||||||||||

SURFACE FINISH

| Marks | Surface state | Surface Roughness range | ||||||||||||||||

| B | Bright finish | Surface Roughness:0.2μm-0.35μm | ||||||||||||||||

| R | Stone finish | Surface Roughness:0.3μm-0.45μm | ||||||||||||||||

| S | Sand finish | Surface Roughness:1.8μm-2.0μm | ||||||||||||||||