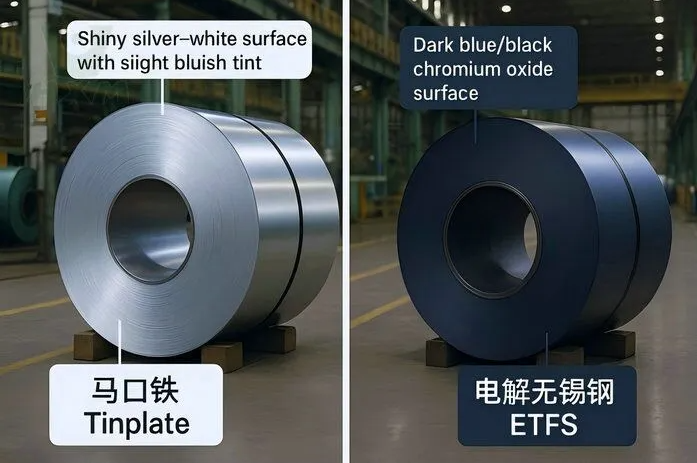

Tinplate printing, also known as tin packaging printing, involves applying decorative or informational designs onto tinplate surfaces to create items such as decorative boxes and containers. Tinplate consists of steel coated with a thin layer of tin, making it ideal for packaging a wide range of products—including confectionery, food, cosmetics, and tobacco. This essay details the key steps in tinplate printing, from design preparation to finishing, emphasizing the specialized techniques and considerations inherent to this craft.

1. Design Preparation and Plate Making The process begins with careful design planning and the creation of printing plates. This stage is critical, as it defines the final visual outcome, requiring precise attention to color schemes, patterns, and branding elements.

2. Tinplate Pretreatment Before printing, the tinplate surface undergoes pretreatment to ensure optimal ink adhesion and print quality. Steps include dust removal, degreasing, and the application of a primer, all of which enhance ink receptivity and adhesion.

3. White Ink or Coating Application Depending on the design requirements, a white ink or coating is applied. White ink allows selective application, preserving areas of exposed or transparent tin, while a full white coating provides a uniform base for subsequent color layers.

4. Color Printing (CMYK or Pantone) Using lithographic offset printing, the artwork is transferred onto the tinplate via a blanket cylinder, leveraging the repellent properties of ink and water. Adjustments are made to account for tinplate’s specific characteristics—such as heat resistance, adhesion strength, and hardness—though the core principles align with paper printing technology. Both CMYK and Pantone color systems can be utilized according to design needs.

5. Drying Post-printing, the ink is dried or cured to ensure durability and strong adhesion. Common methods include heat curing and UV curing, each selected for efficiency and effectiveness in bonding the ink to the tinplate surface.

6. Varnishing Once the ink is fully dried, a protective varnish is applied. This not only enhances scratch resistance and longevity but can also add aesthetic effects—such as matte or soft-touch finishes—to improve the visual and tactile quality of the final product.

Tinplate printing is a detailed and sophisticated process that merges artistic design with technical precision. Each stage—from initial design to final varnishing—is executed with care to produce vibrant, durable, and visually appealing metal packaging. Mastery of these techniques allows artisans to transform simple tinplate into striking, functional artworks.